ic programmer|chip test|automated programmer system|Automated Device Programmers

Microelectronics

Provide chip testing and programming services

2026-02-06

2026-02-05

2026-02-04

2026-02-03

2026-02-02

2026-01-31

Address:3rd Floor, No. 4 Factory Building, No. 550, Jujin Road, Zhangpu Town, Kunshan City

Phone:0512-57225603

Mobile:13812682041Miss Zhao

Email:jessie@ptchip.com.cn

author::Microelectronicsrelease date:2020-11-21Viewers:2887

The first professional exhibition after the epidemic, July 9-11, Dongguan·Guangdong Modern International Exhibition Center, the three-day 4th China Electronics Manufacturing Automation & Resources Exhibition and 2020 CMM China Masks & Manufacturing Exhibition has successfully concluded!

Hundreds of companies organized a group visit, hundreds of exhibitors, and 10,000 new products appeared in a concentrated manner, covering the entire automatic process of electronics manufacturing, attracting attention and meeting expectations.

queue

Long line

Long queue~

It's a picture of the three-day exhibition that has never been dropped

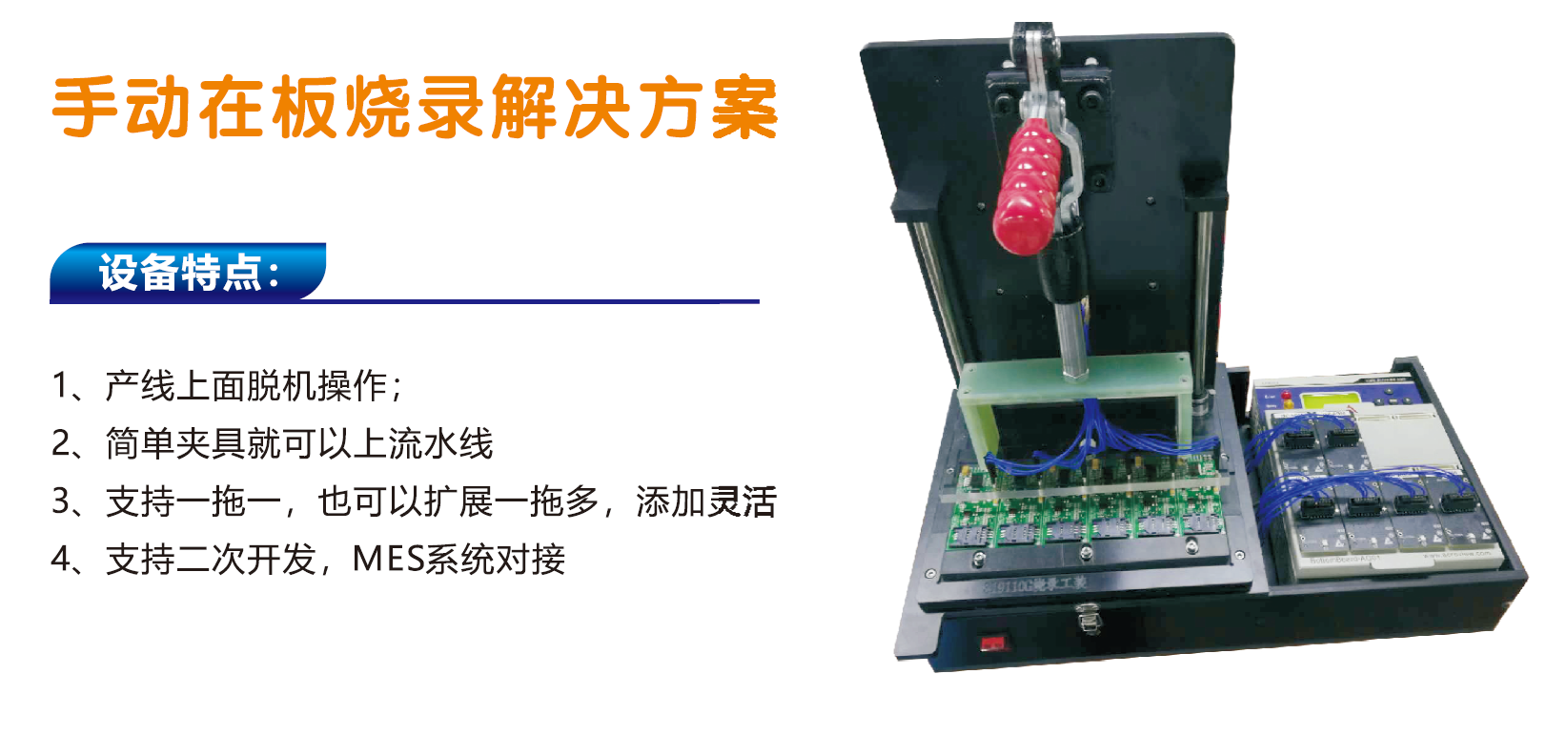

Acroviewtech not only launched a new high-performance automatic burner IPS5000 and UFS mass production and engineering burners at this exhibition, but also brought a fully automatic online burning solution.

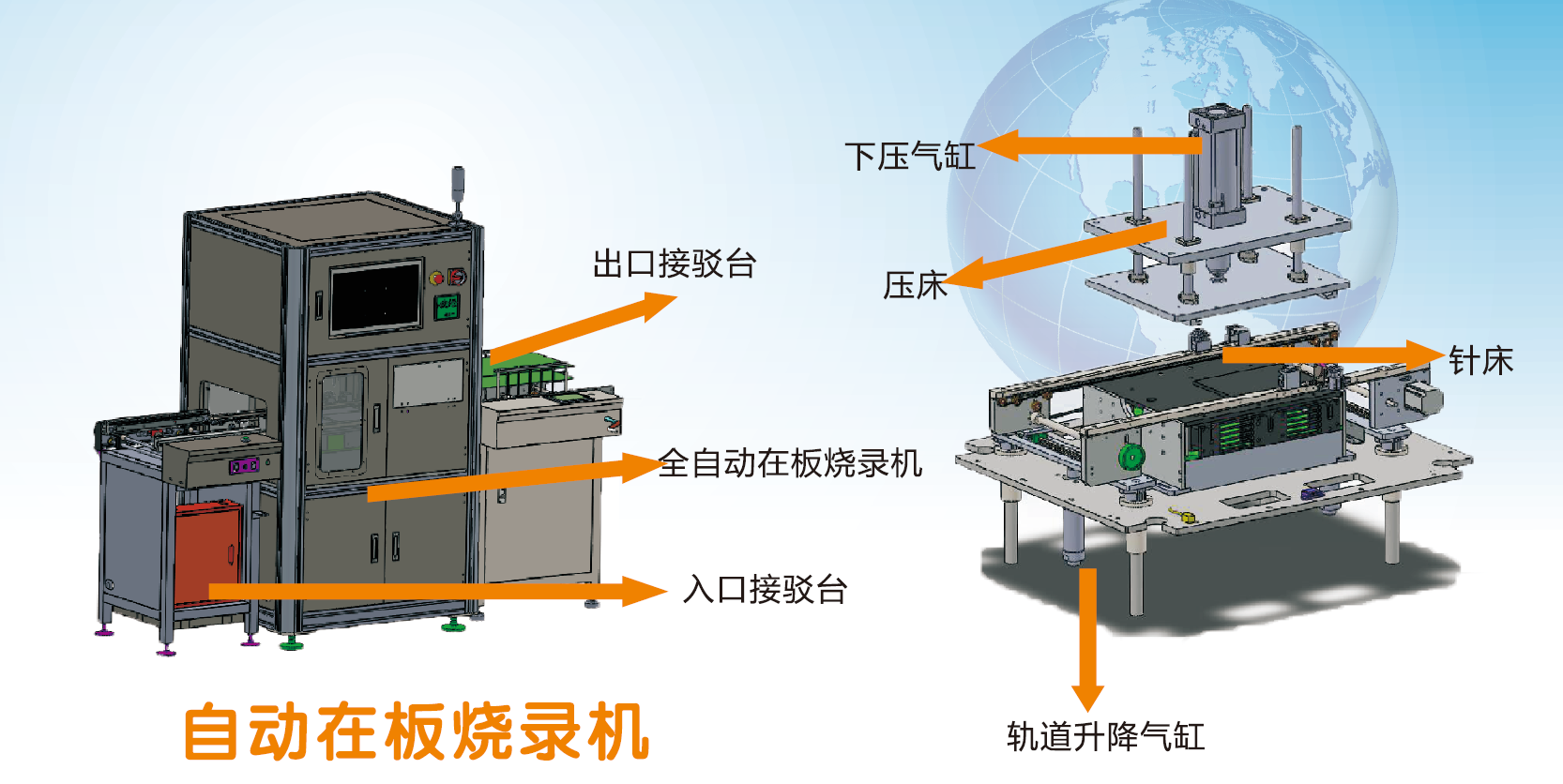

Fully automatic online programming solution

Features:

1: It can be placed after reflow soldering, wave soldering, board loading machine, or in front of the online splitting machine, to achieve true streamlined automatic operation

2: Possess a complete MES system interface, which can save a complete burning data record, making the entire burning process checkable and traceable;

3: Detachable programming needle bed, different products only need to replace the programming needle bed, the transfer time is less than 10 minutes

Main frame | Main frame |

Display screen | AOC |

Display screenDisplay screen | Industrial PC |

way to control | Panasonic PLC programmable controller |

transfer method | One-stage orbital transmission |

Exercise | Linear guide and ball screw width adjustment |

PCB barcode recognition | Entrance scanner recognition |

PCB programming interface positioning method | Needle bed positioning needle precise positioning |

Burning method | Automatic press down programming |

PCB management method | Press the dot under the marking pen at the press |

Model conversion time | Less than 10 minutes (but not including ROM data transfer time) |

Secondary development interface | Remote control (Matlab, Labview, Scilab or Python)& VC, VB, C# ,Java… |

Whether to support MES system connection | stand by |

Support network | Ethernet |

Dimensions | 950*850*1850mm(L*W*H) |

Adapt to PCB size | 50*50-450*330mm(L*W)(Size can be customized) |

Board height | 920~950mm |

power supply |

Previous:Acroview latest official software AP8000_V1.04.52 released Next: The second day of CMM exhibition | Acroviewtech's UFS burner booth was full of rewards, and it Hot tags: |